OUR PRODUCTS

Mechanical Steel Products and Services

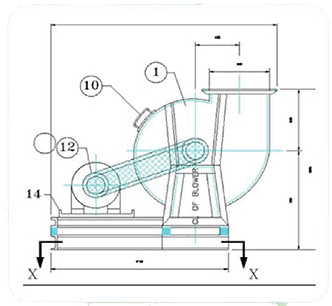

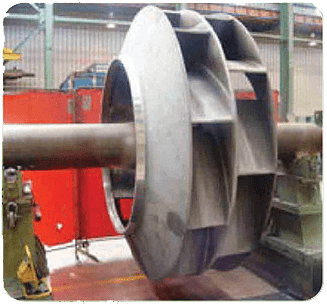

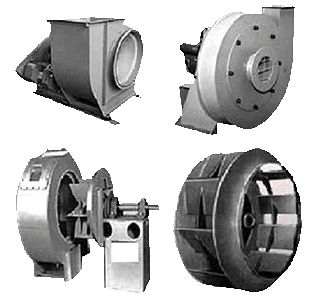

BLOWER & IMPELLER

- IDF FOR BOILER

- IMPELLER FIBRE CYCLONE

- IMPELLER NUT SILO

- IMPELLER KERNEL SILO

- IMPELLER LTDS

- IMPELLER DESTONER

- IMPELLER PNEUMATIC NUT TRANSPORT

- IMPELLER KERNEL TRANSPORT

- IMPELLER KERNEL BULK SILO

- ETC

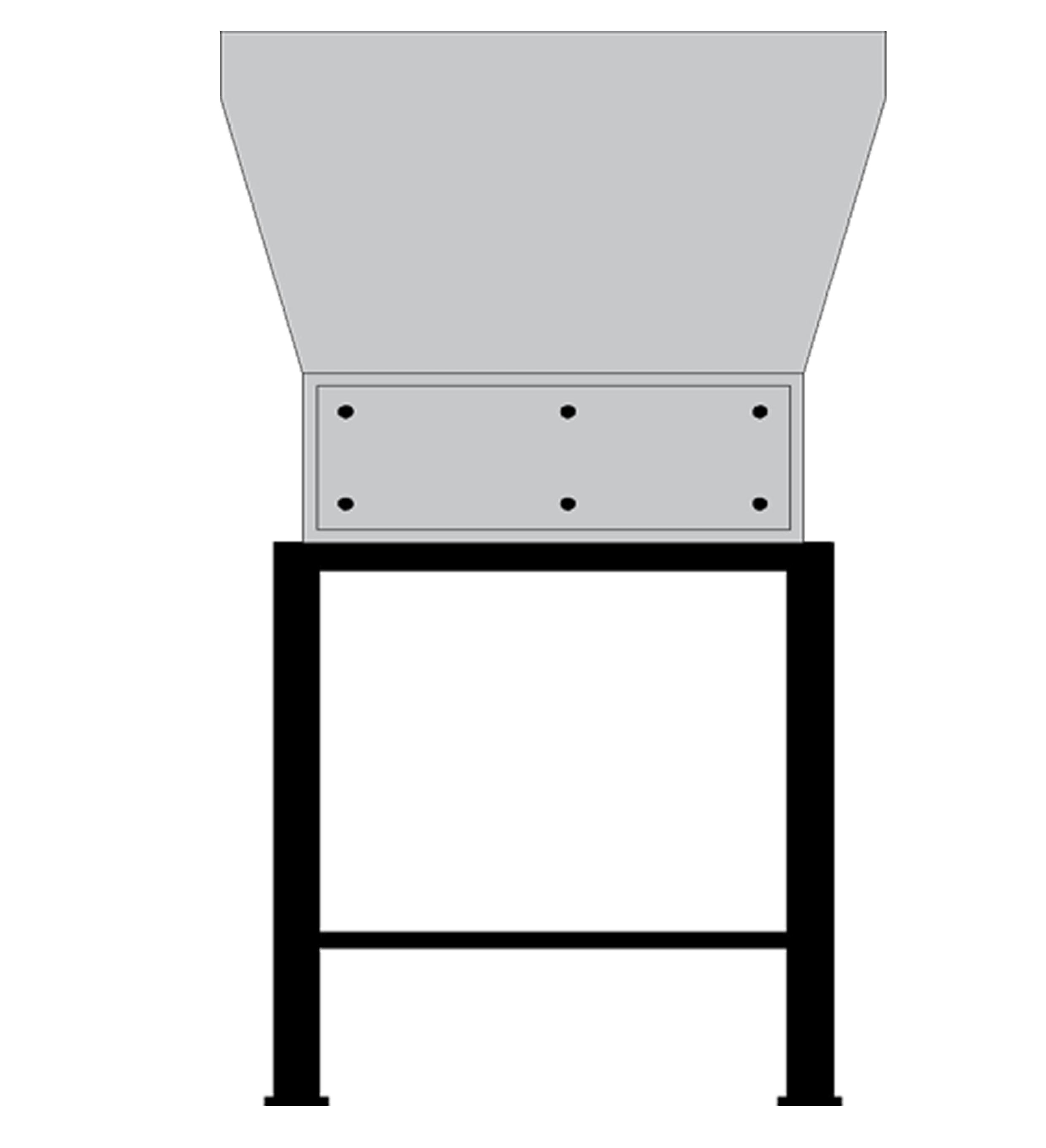

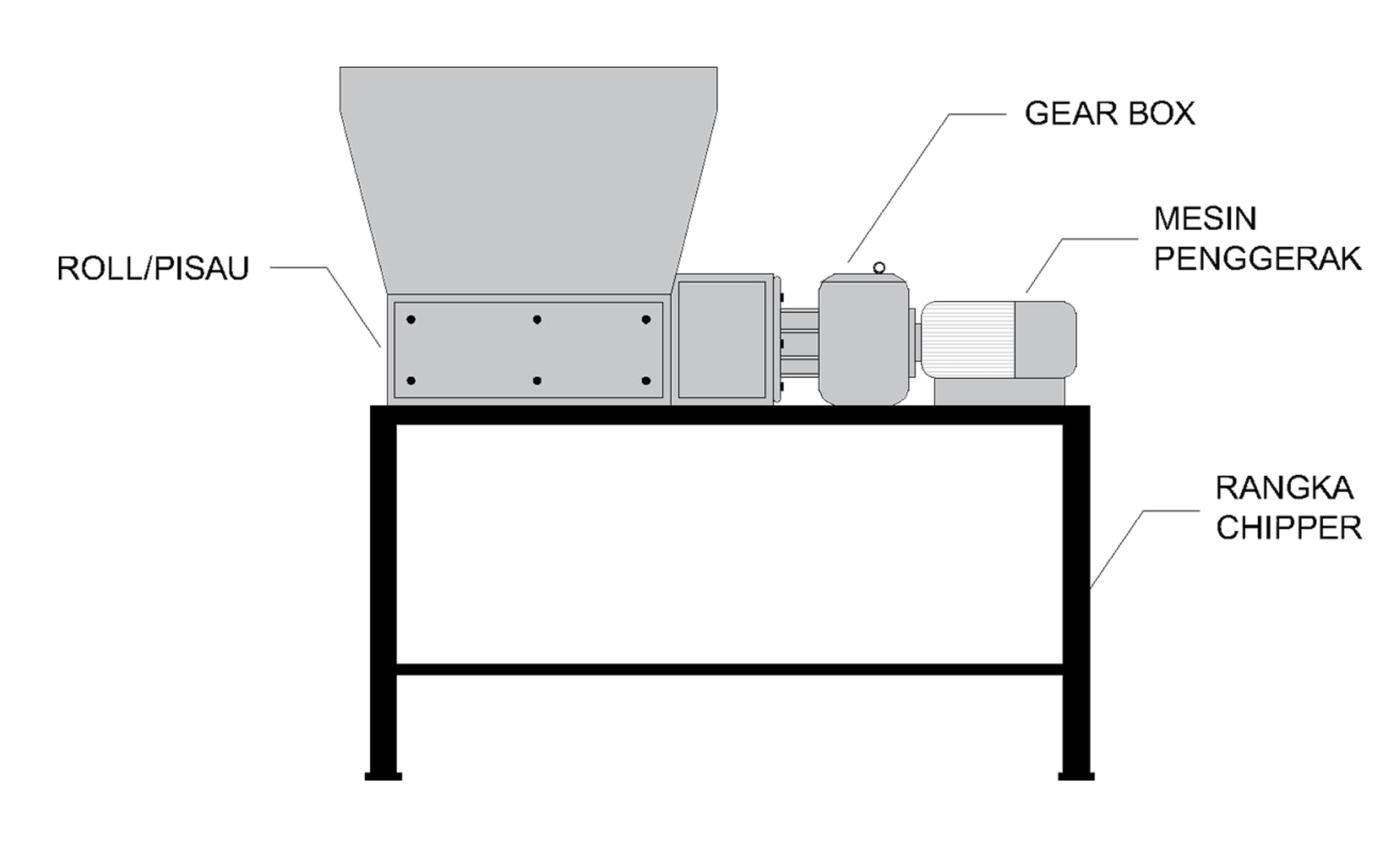

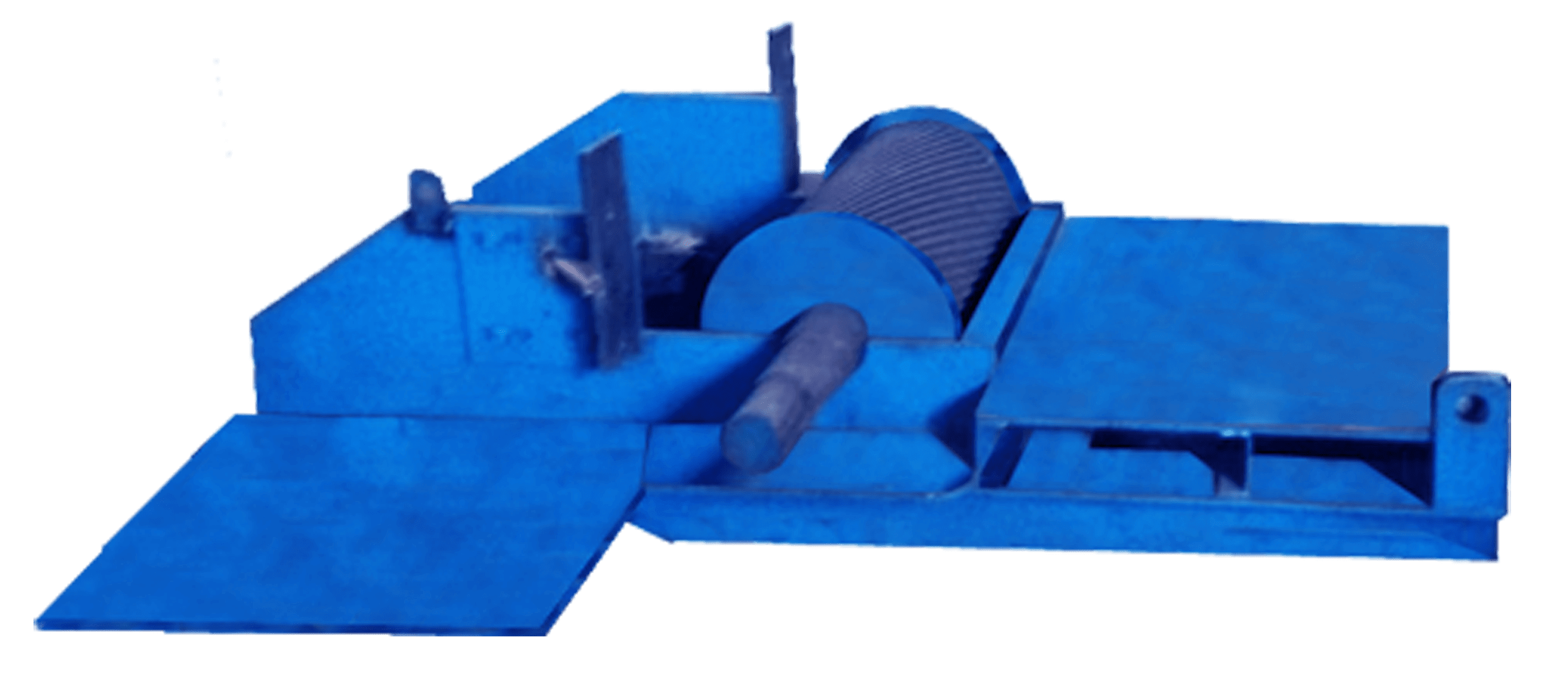

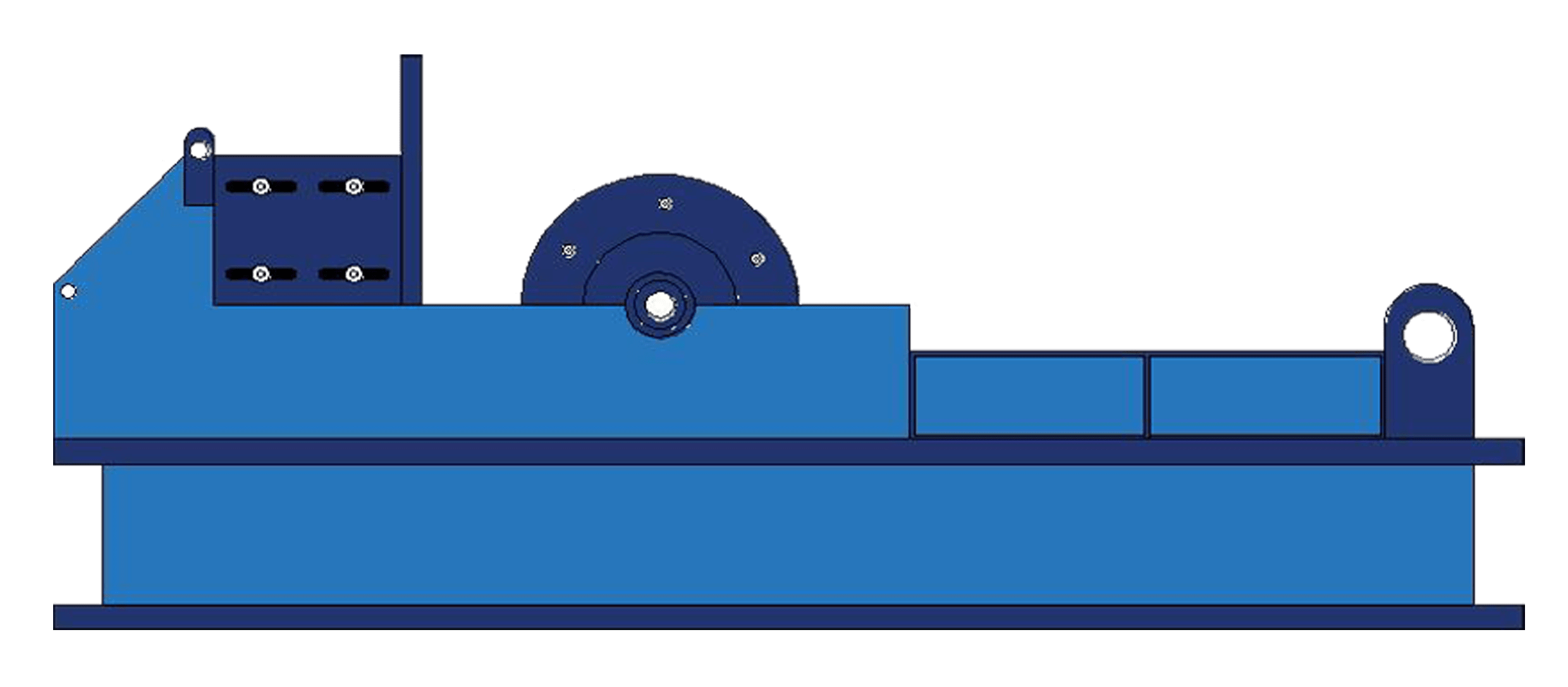

CHIPPER

Empty fruit bunch (efb) by various length for :

- Boiler fuel

- Composting fertilizer : shred oil palm fronds, sherd oil palm (treat trunk), shred wood (wood waste)

CAPACITY : 1-3 TPN/HR

POWER : 30-40 KW

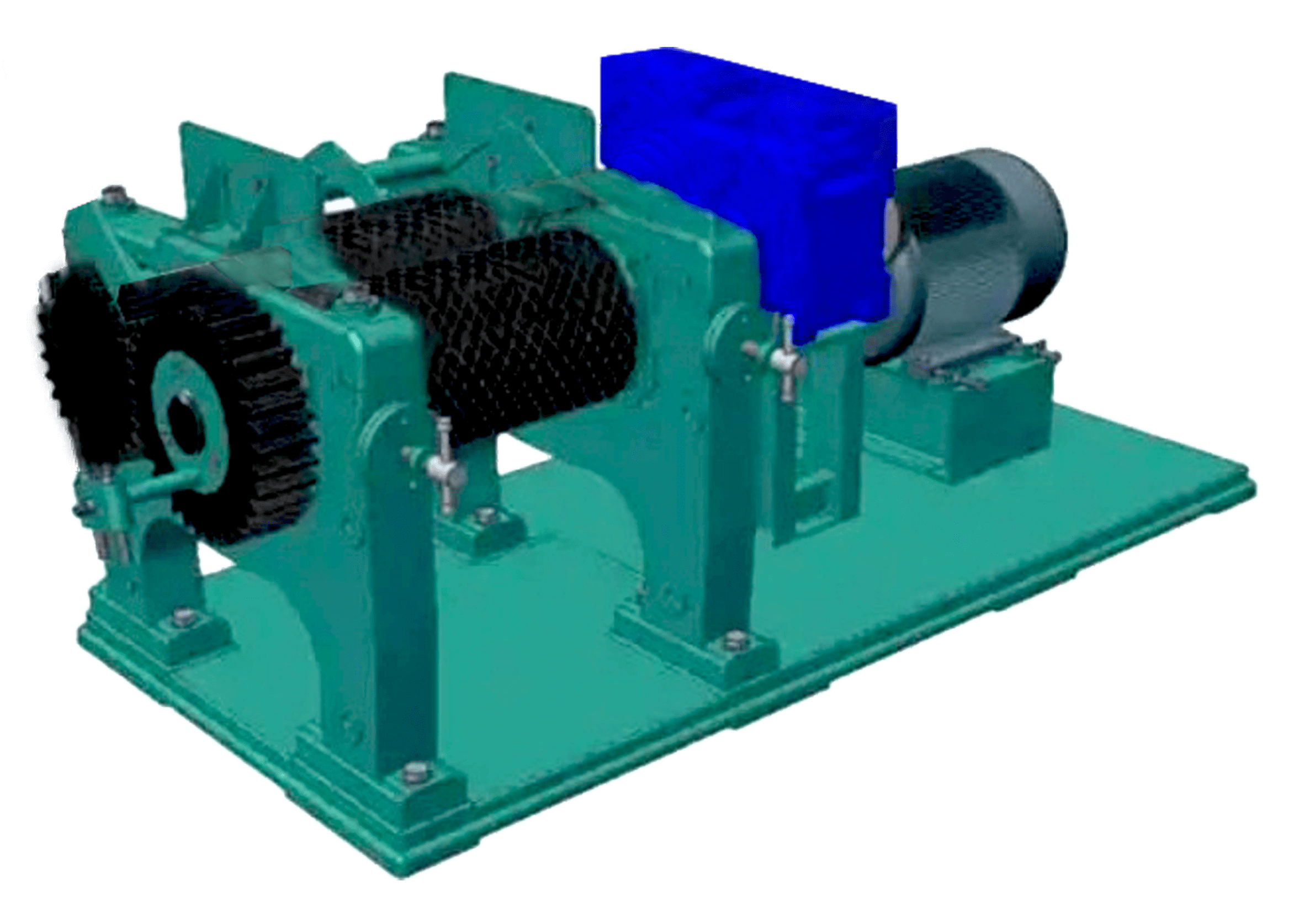

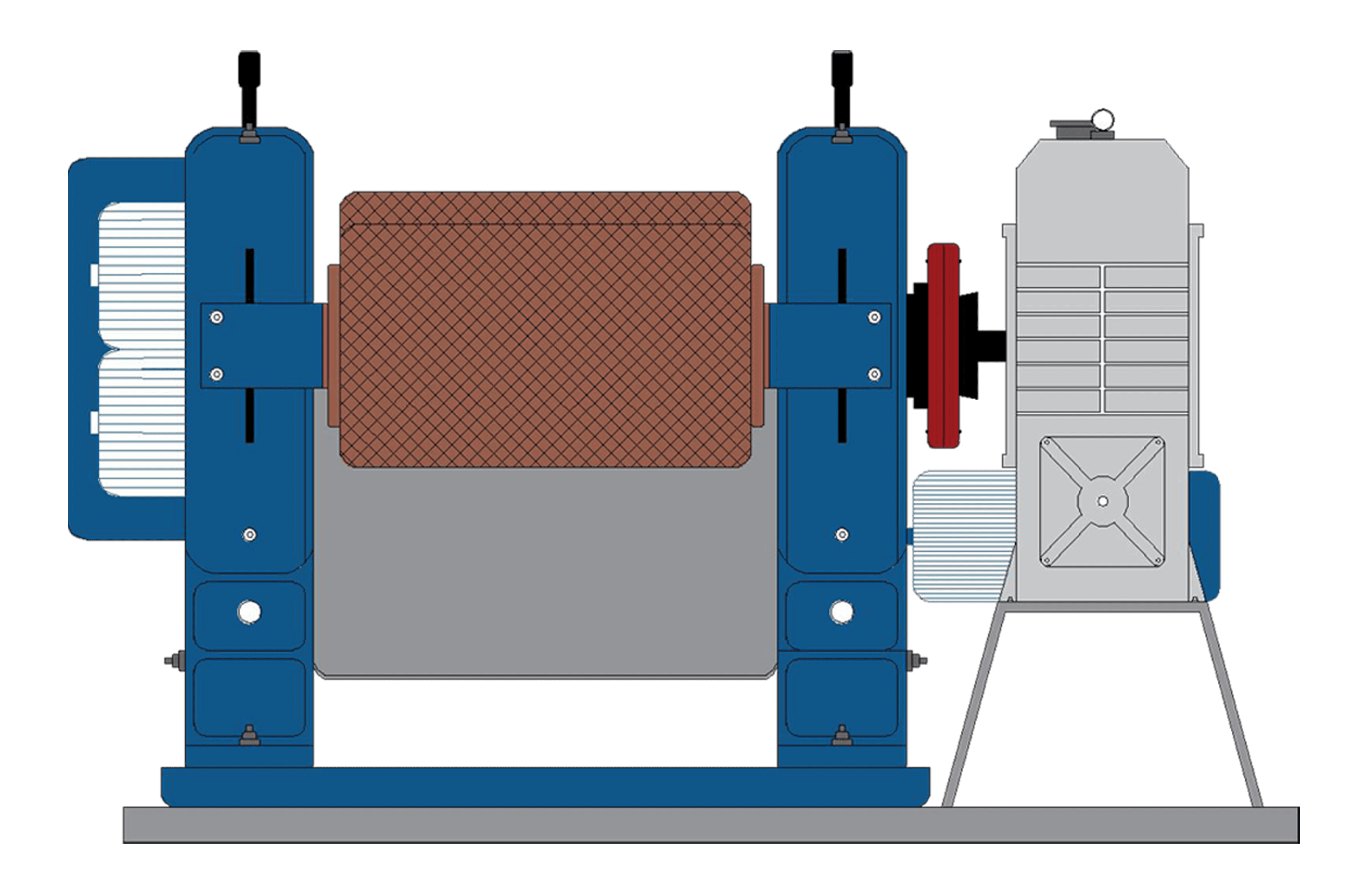

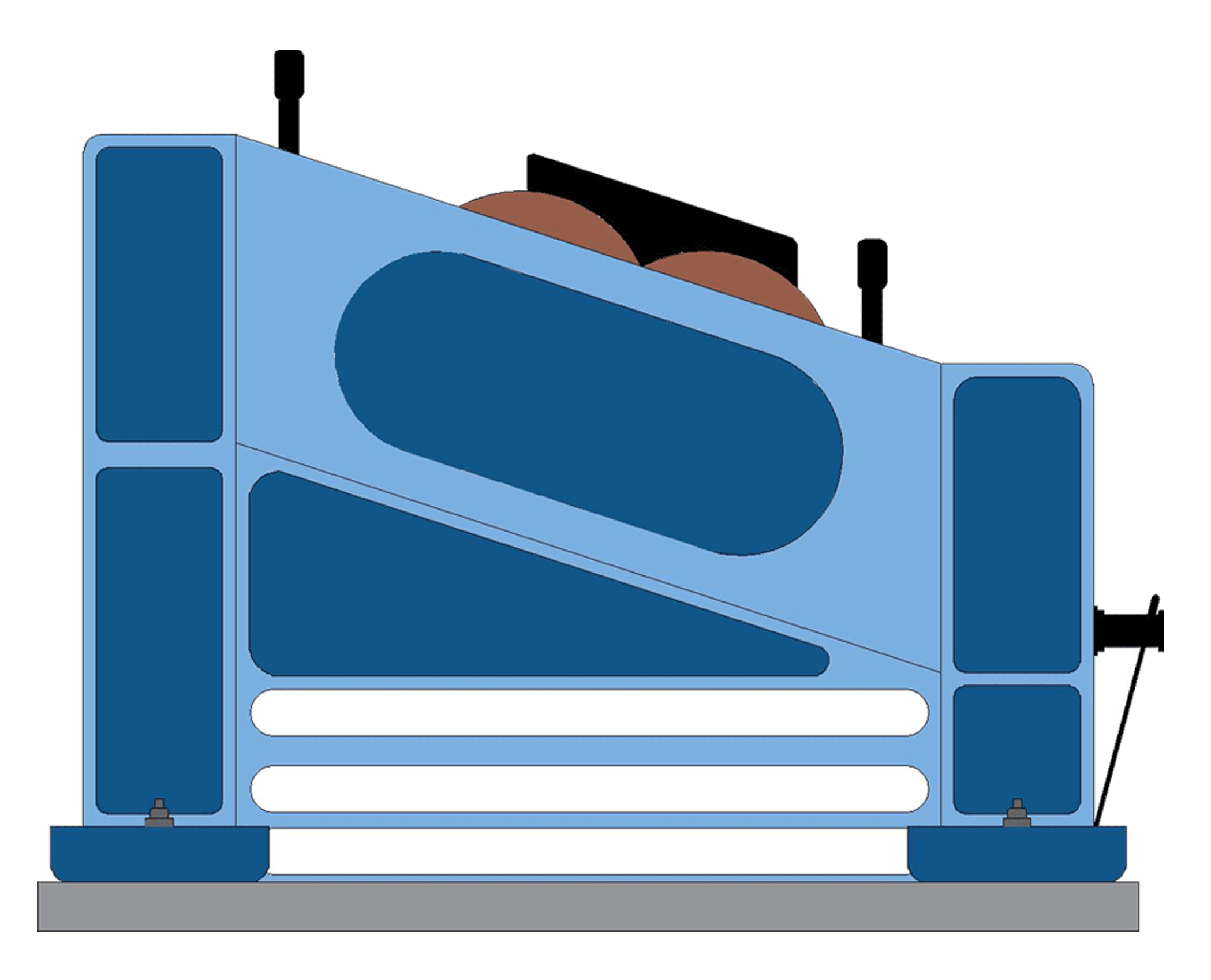

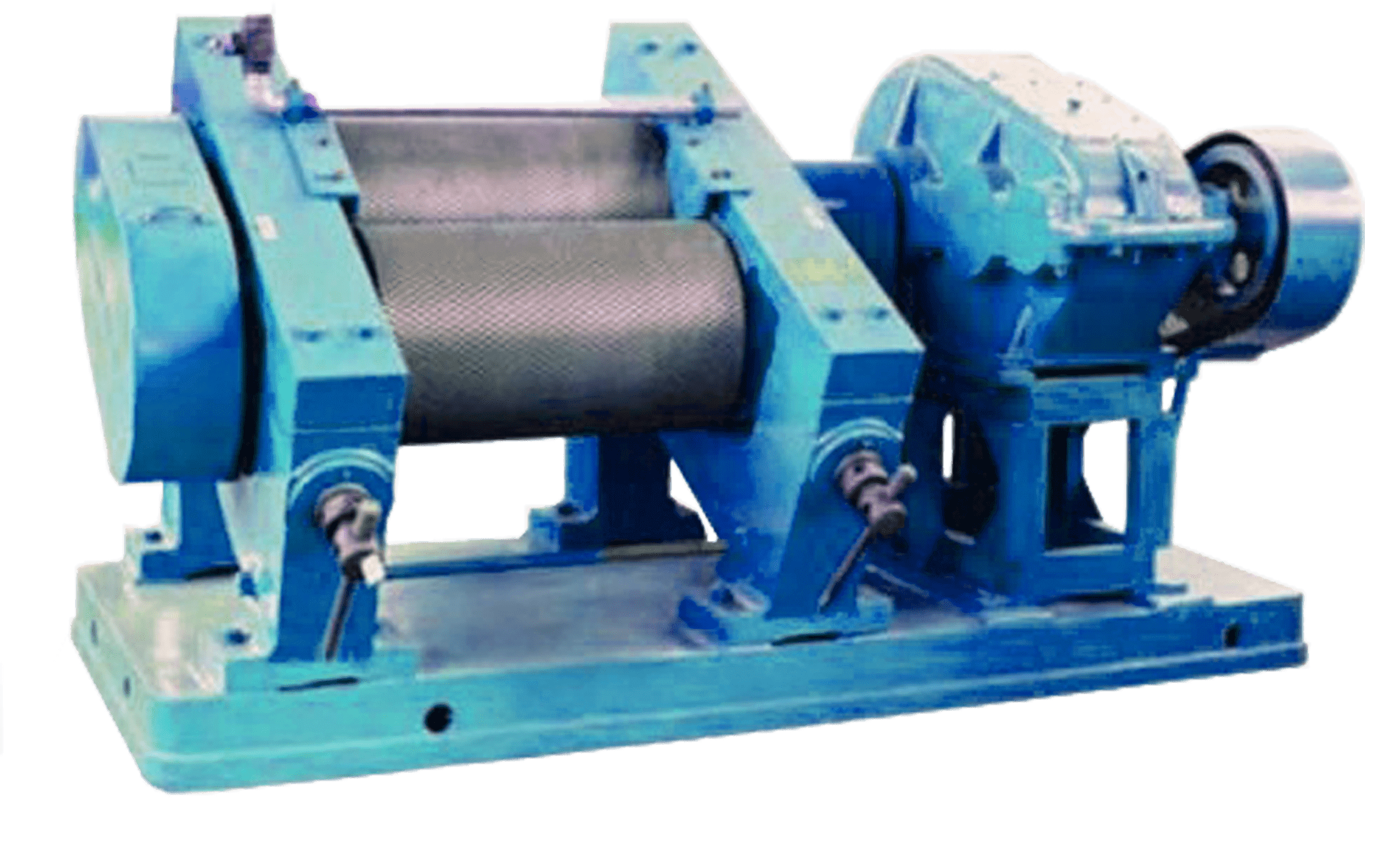

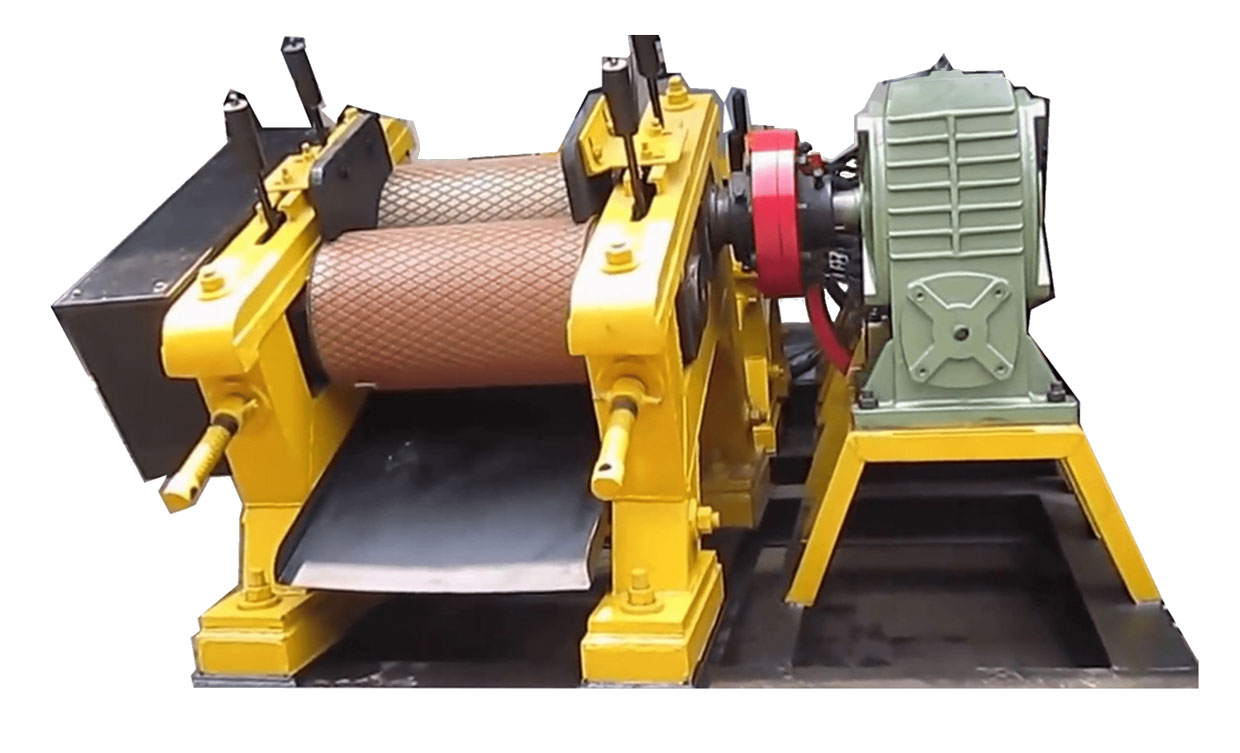

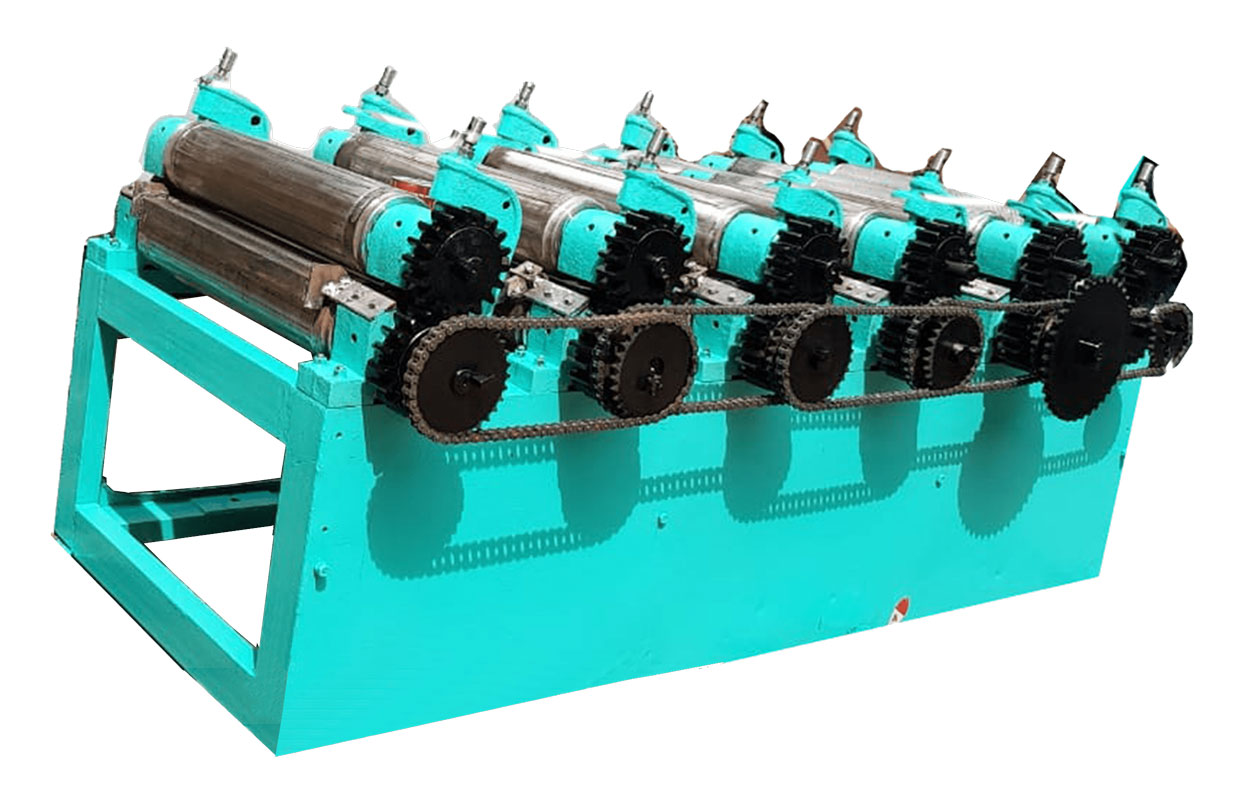

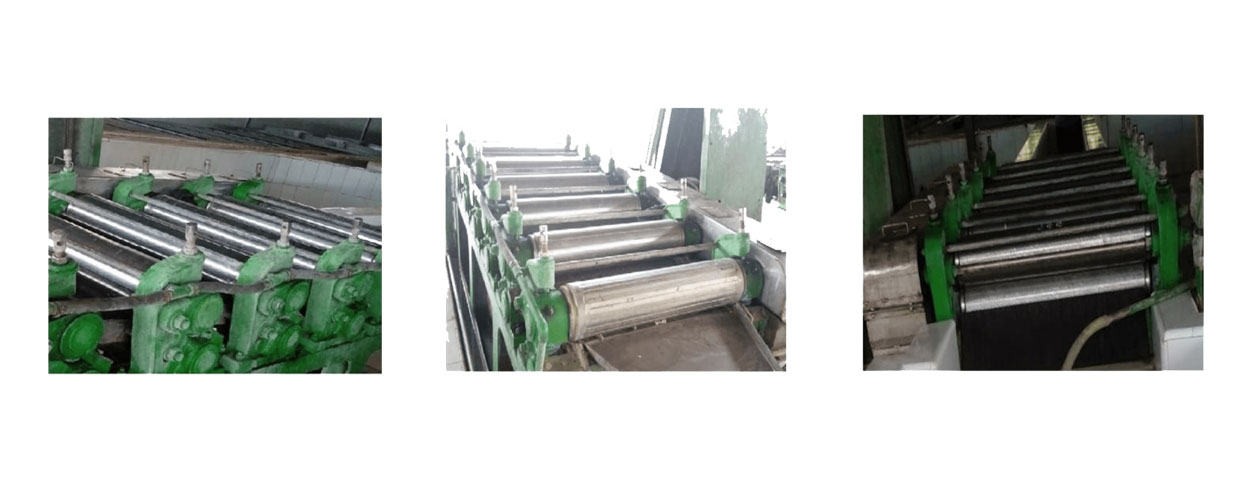

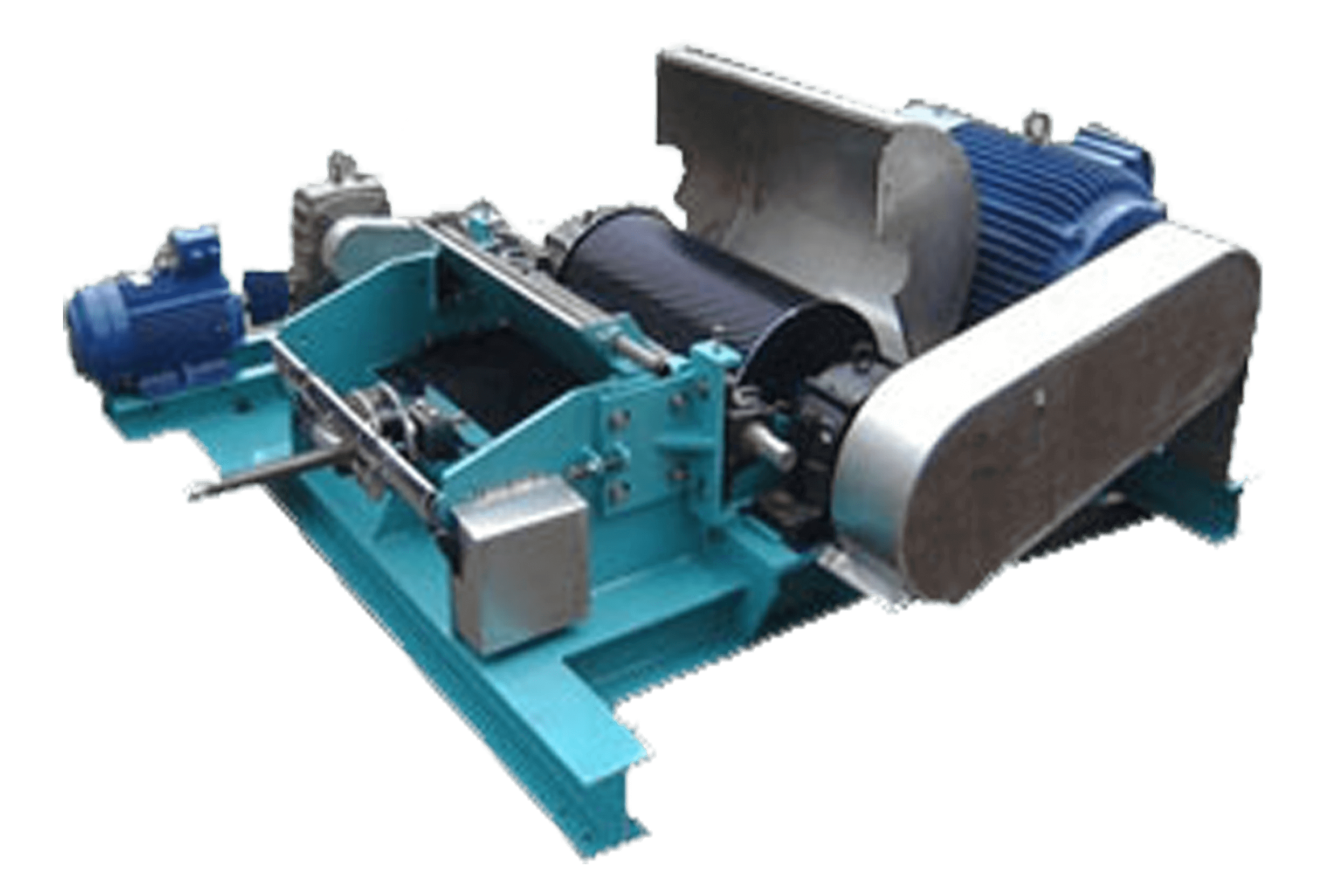

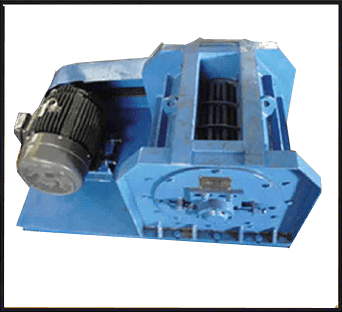

CREPER FOR CRUMB RUBBER PROCESSING

Used in the intermediate stage of processing for intermediate and final shearing of rubber. Whole machine has compact structure, high dehydration efficiency easy and convement feeding system standard transmission noise standard power consumption.CREPER TYPE HCPJ15

- 2 ROLLS CREPER 15” WITH DIAMOND SHAPED-SURFACING

- LENGTH 28”

- ROUND SEL GEARS, T28 & T25

- GEARBOX 20 : 1, RADICON/EQUIVALENT

- ELECTROMOTOR 45 KW + PANEL

FOUNDATION & ASSEMBLY

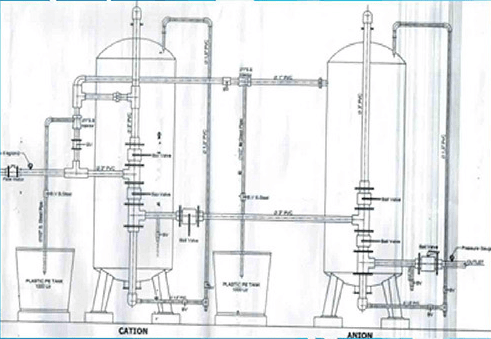

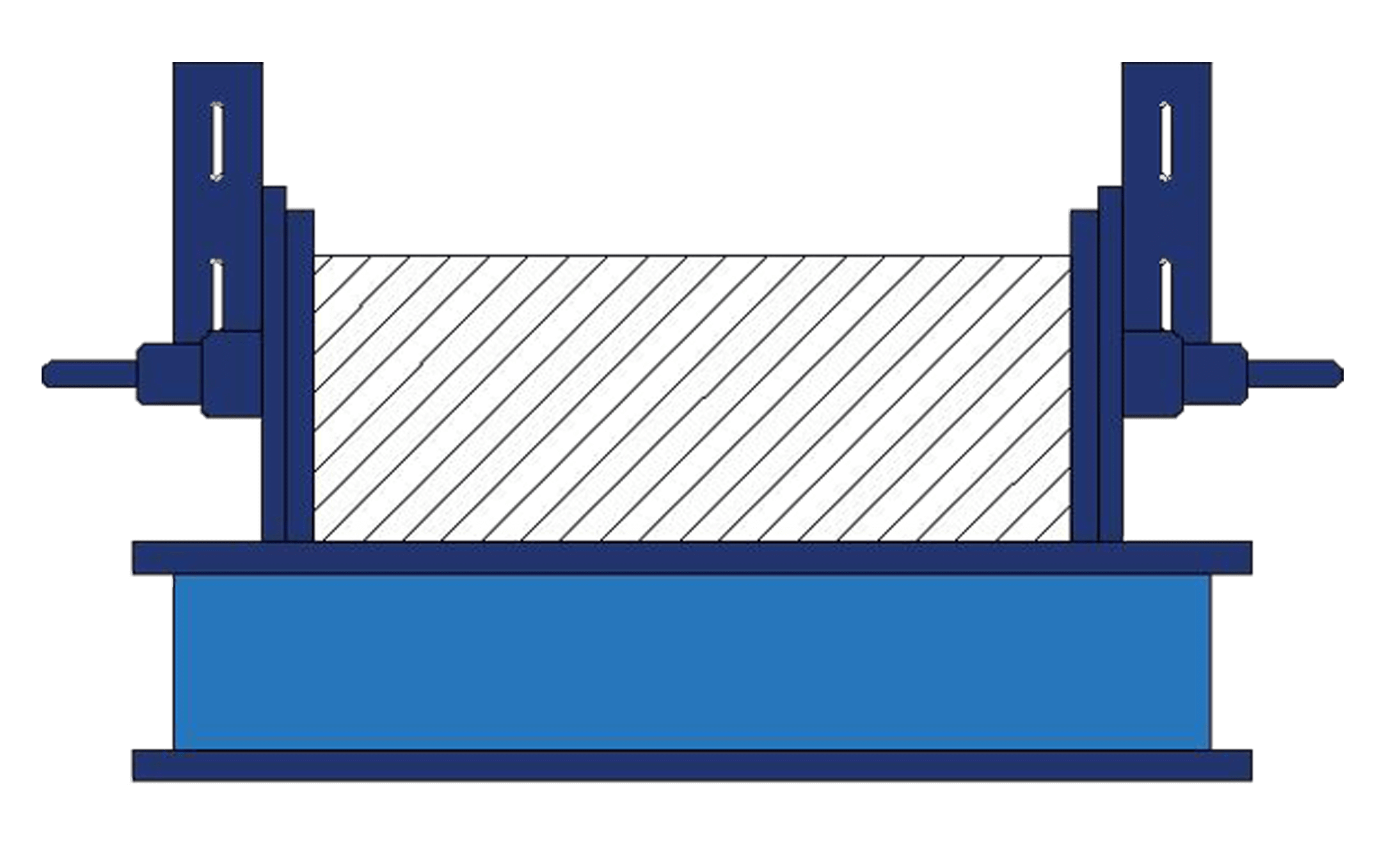

DEMINERALIZATION ON PLANTS

Cation anion tank

Produce demineralized water by means of ion exchange technology

Flow rates for standard modules :

Up to 50 m3/h

Imroved aesthetics and rugged design

User friendly, low maintenance and easy to install

Simpler distribution and collection systems

Quick availability

Automatic, two tank plants

Cation tank and anion tank

Tank material : fibreglass filament roving

Major applications :

Boilers feed water, chemicals, swimming pools

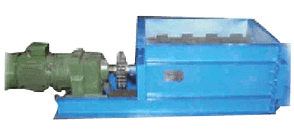

EMPTY BUNCH CRUSHER

- Model : hebc-3060

- Capacity : 30-60 mt ffb/hour

- Rollers : carbon steel with hard facing

- Rollers’ speed : 35 and 25 rpm

- Drive : gearmotor 11 kw

- Product : fibres from bunch

FINNED HEATING COILS

Type and size :

- 70 x 70 x 16

- 70 x 90 x 16

- 100 x 100 x 16

The coils are manufactured with copper tubes and a 4.5 mm spaced aluminium fins

High durability

Maximum pressure 10 bar

FRP SAND FILTER

Filament roving makes fibreglass sand filter tanks which allows the production of pipes, tanks, vessels and tubes for use especially in applications where weight, corrosion, electrical insulation, pressure and temperature are critical.

Our sand filter tanks are made in various volume sizes up to ø2500 mm and used in water treatment process in water park or industrial uses.

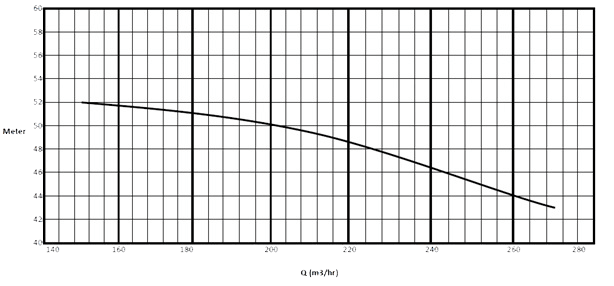

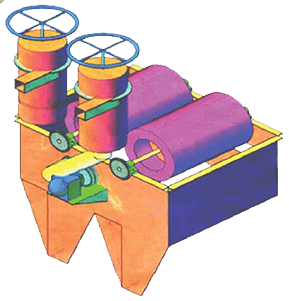

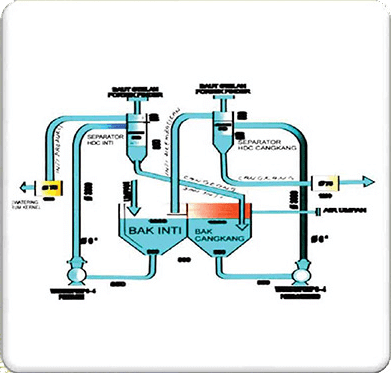

HYDROCYCLONE

High efficiency attainment with qualified materials and design

Types h-hdc – 30/45/60

Fortex feeder

Kewpump/kk pump 6/4

Dewatering drum

Gearmotor 2.2 kw

Ni-hard cones (high lifetime) (optimal)

Panel complete set

LIST PRODUCT HOKINDO

Mechanical steel engineering specialist :

- Creper rubber

- Shredder rubber

- Lump breaker

- Hammer mil

- Roller sheet rubber

- Pre breaker

Rubber processing machinery

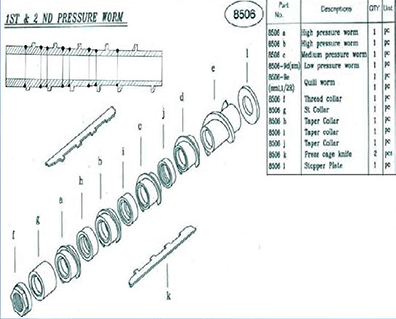

PALM OIL EXPELLERS SCREW

Worms & collars

Cake expeller

Type : hkg=-15 / mbl-15

- Hard facing surface

- Hrc 50-65

- Proven higher lifetime

High endurance

PALM OIL MIL MACHINERY

- Super nut cracker/ripple mill

- Blower and impeller

- Conveyors

- Hydro cyclone

- Thresher drum

- Bunch crusher

- Sand filter tanks

- Water pressure tank

- Cation – anion tanks

- Fiberglass pipes & ducts

- Electrical (instalation, rewinding & repair)

- Dan produk mesin produksi lainnya

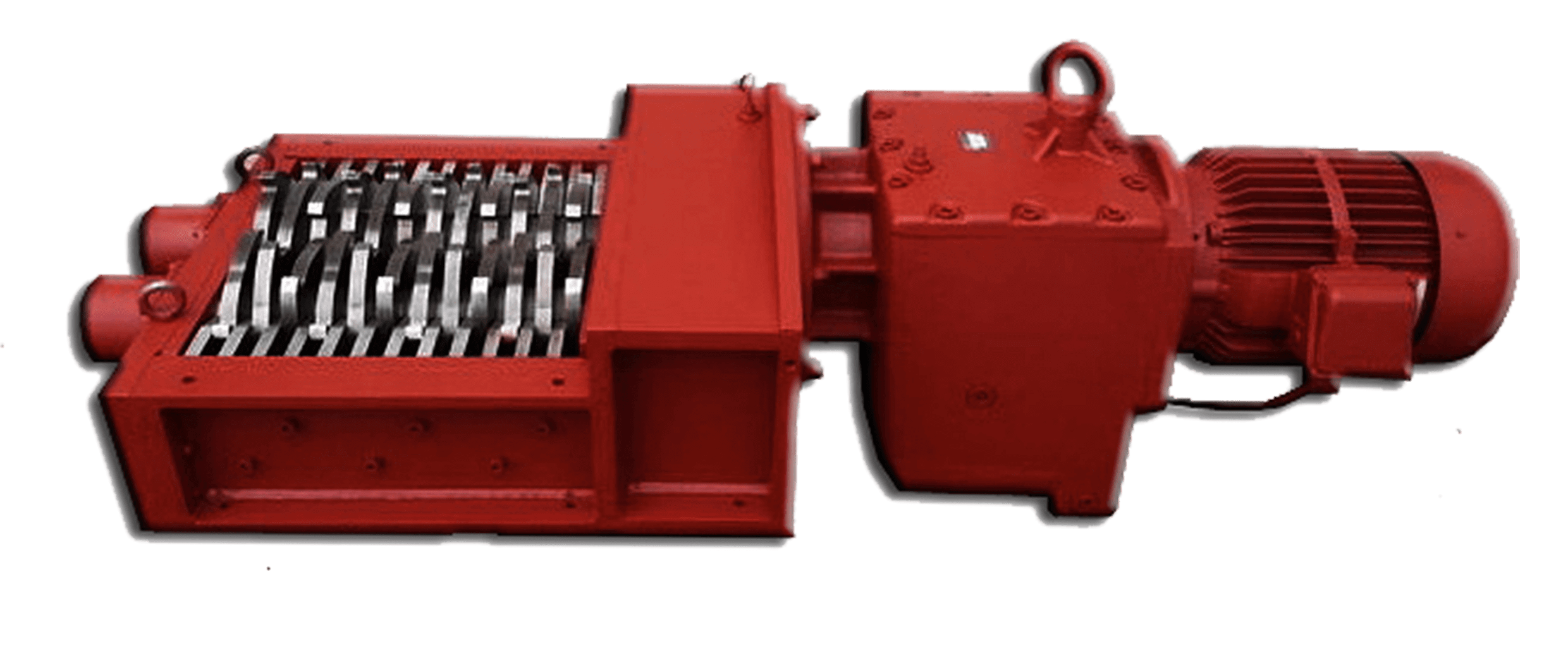

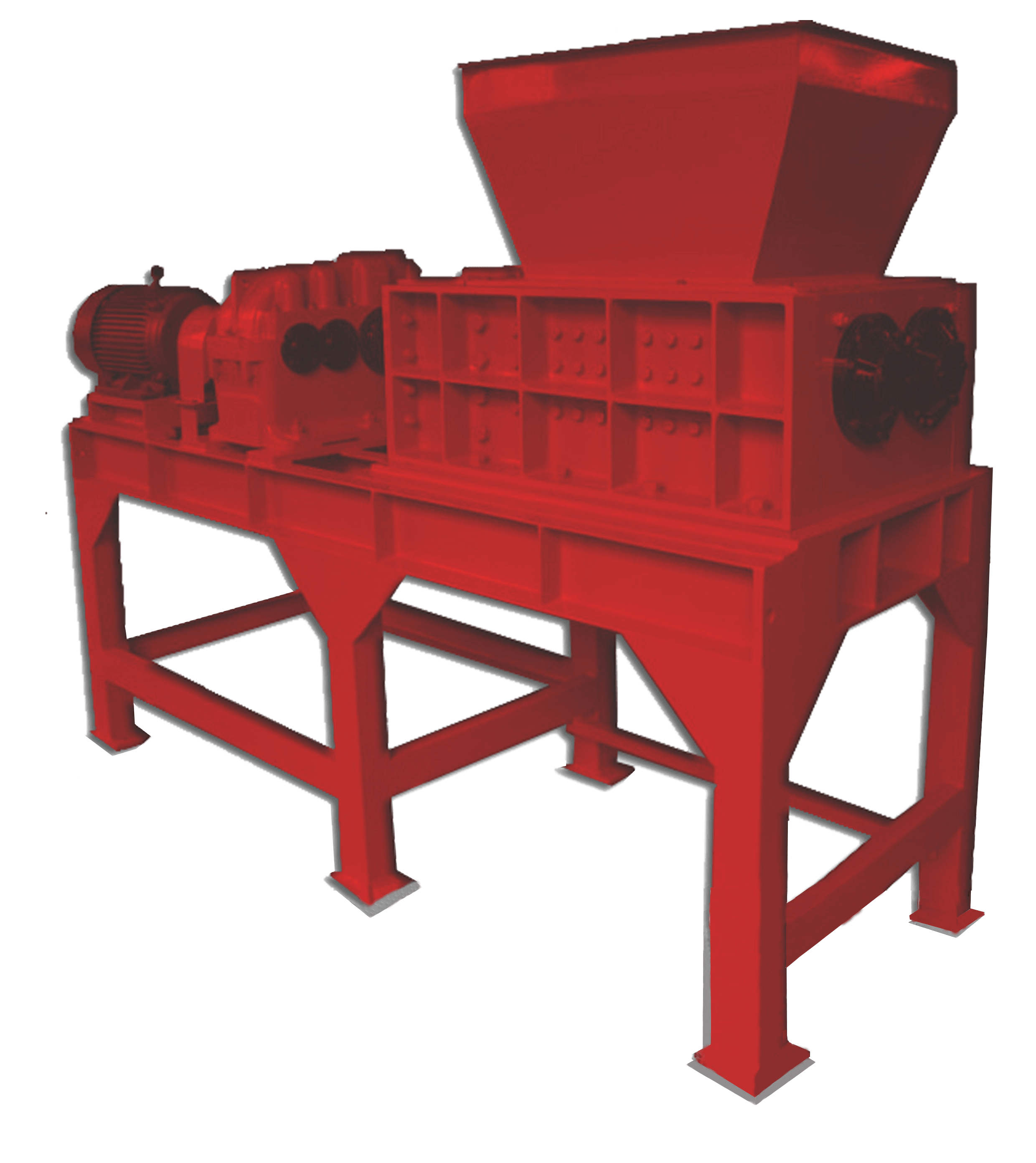

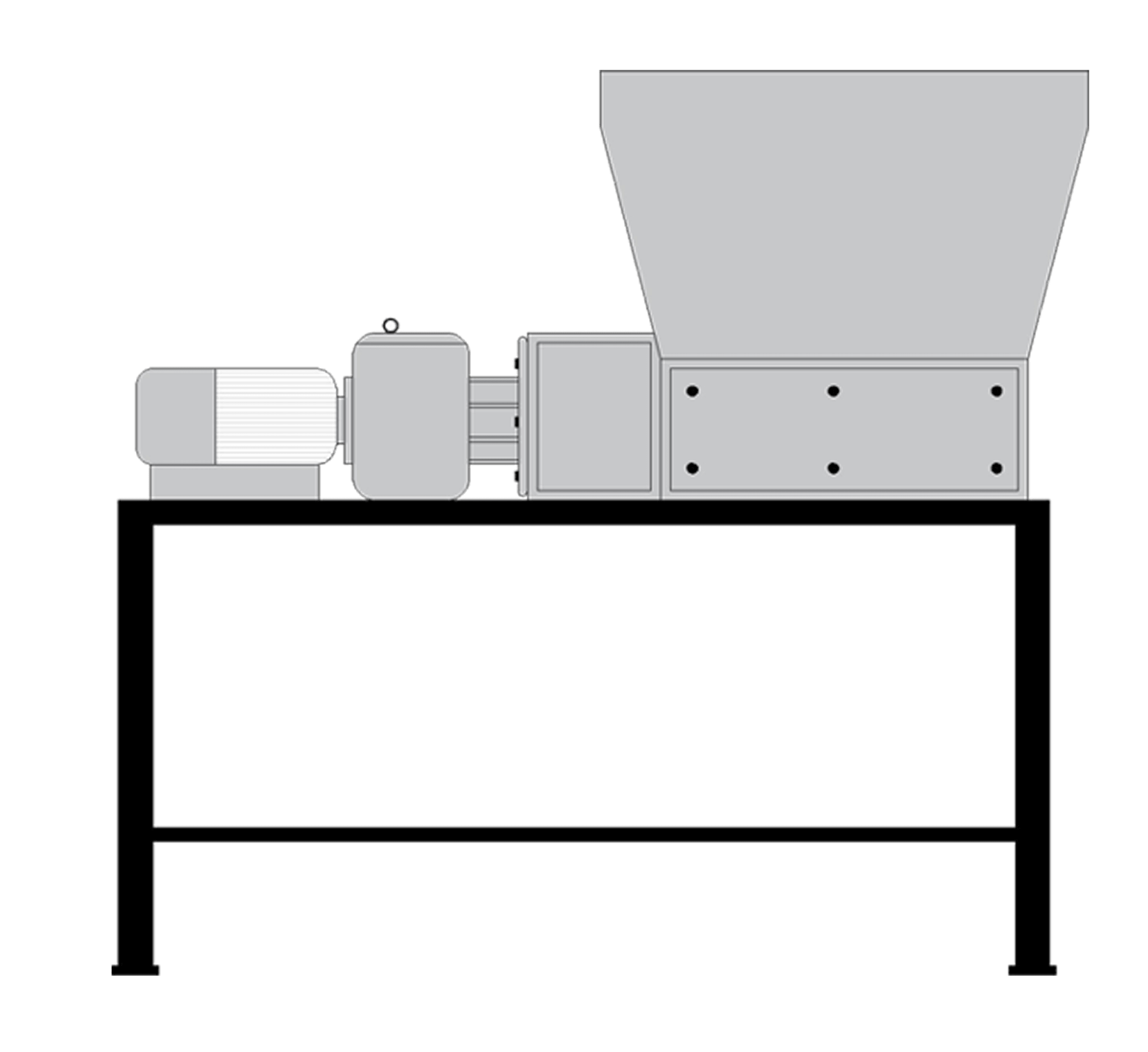

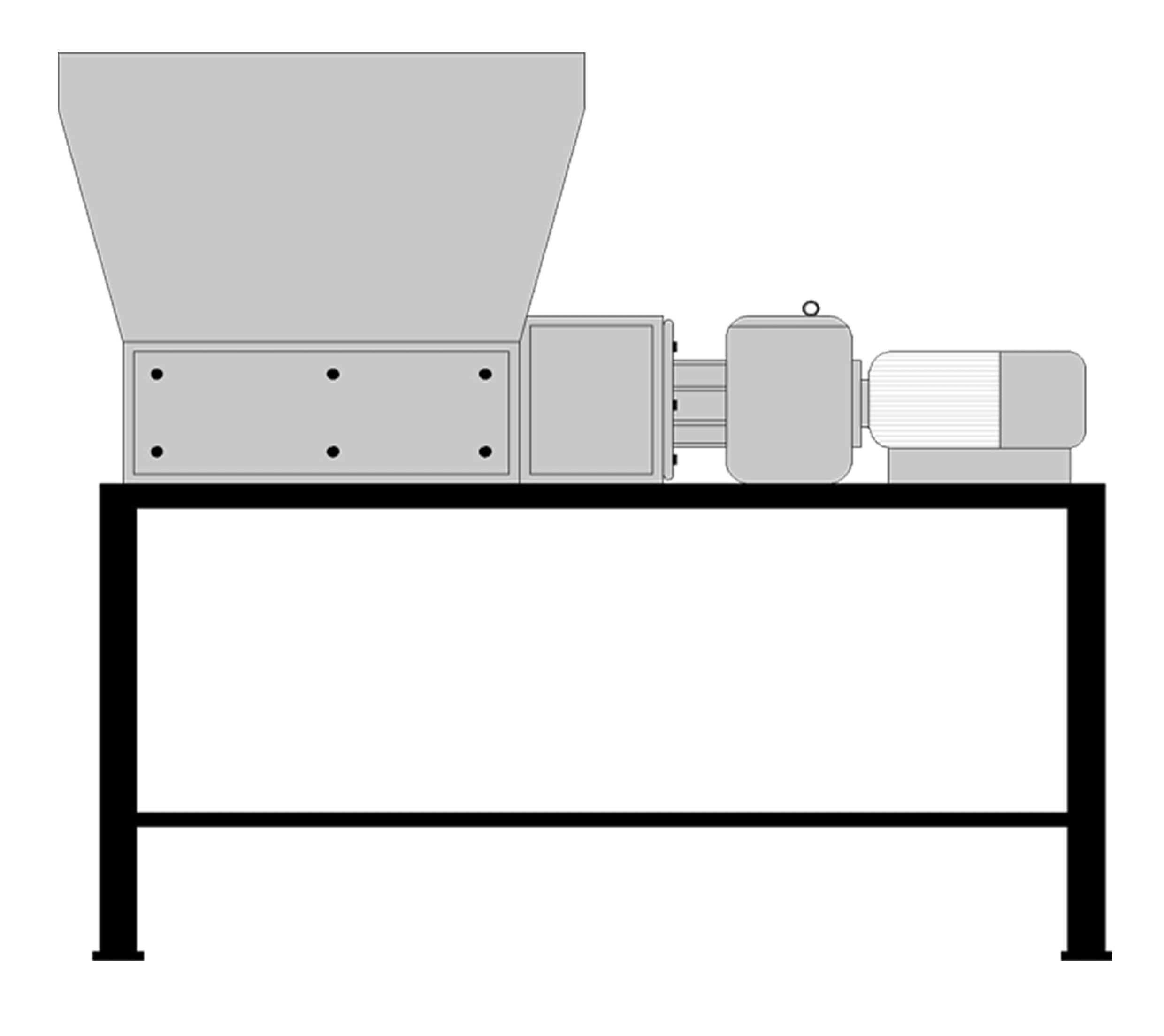

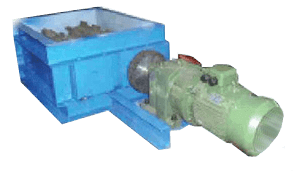

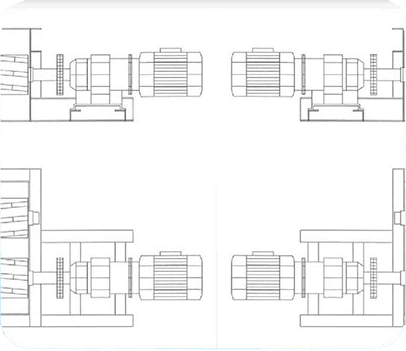

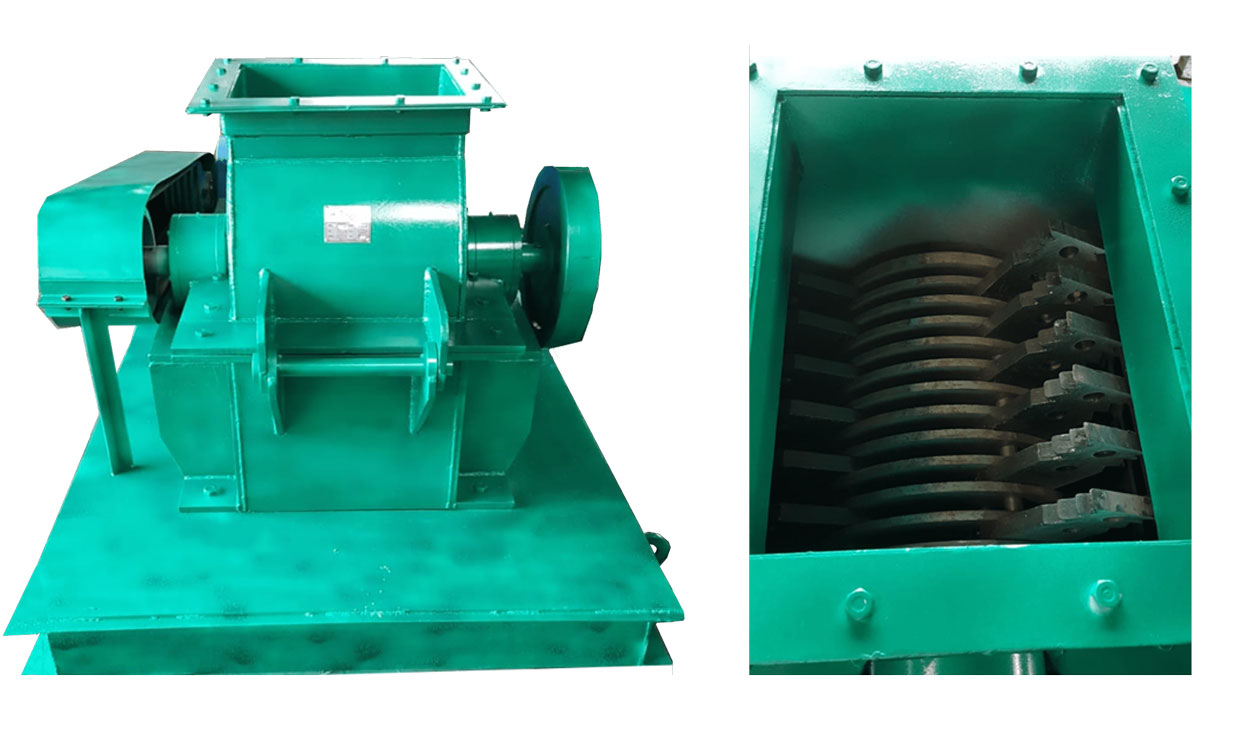

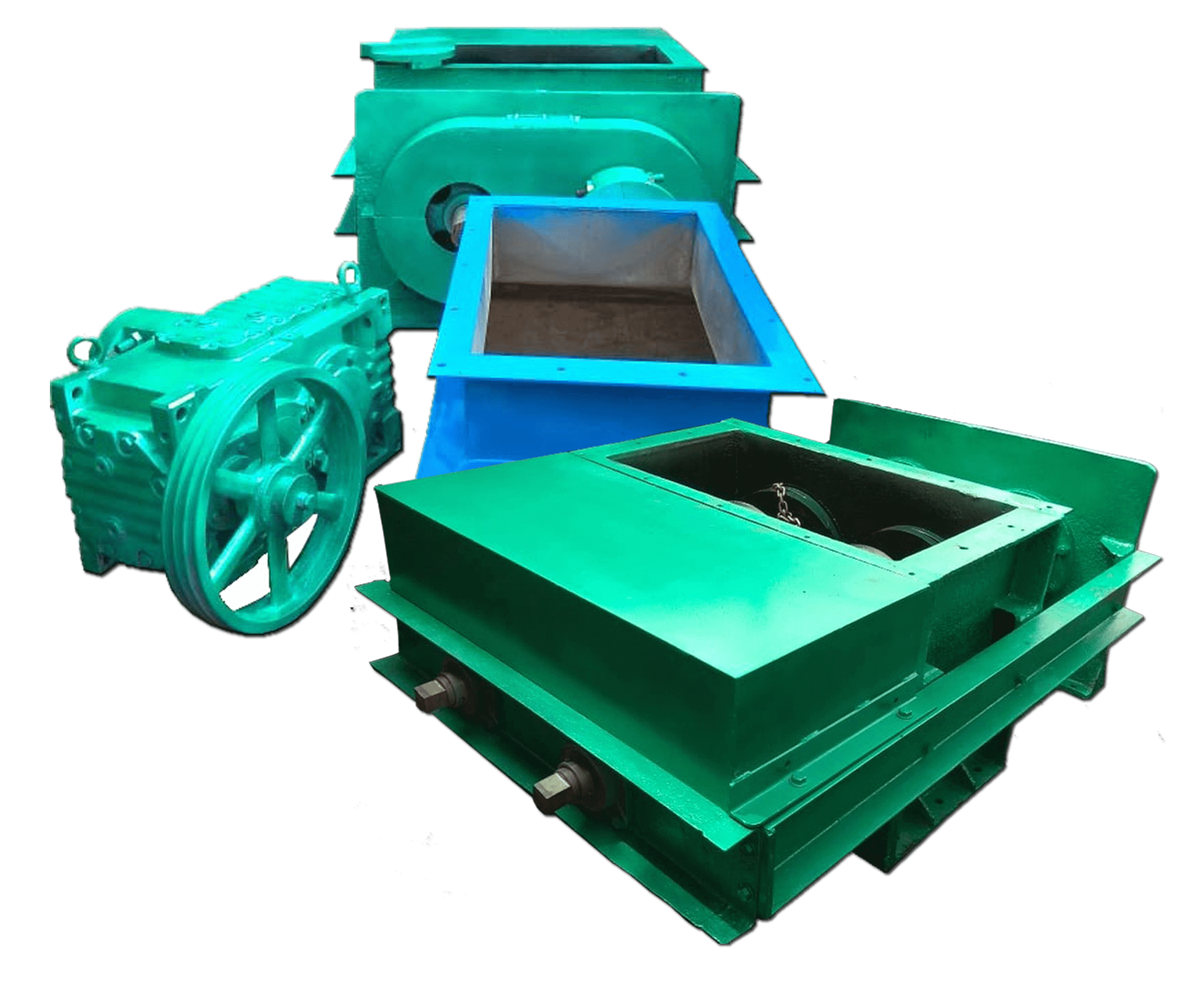

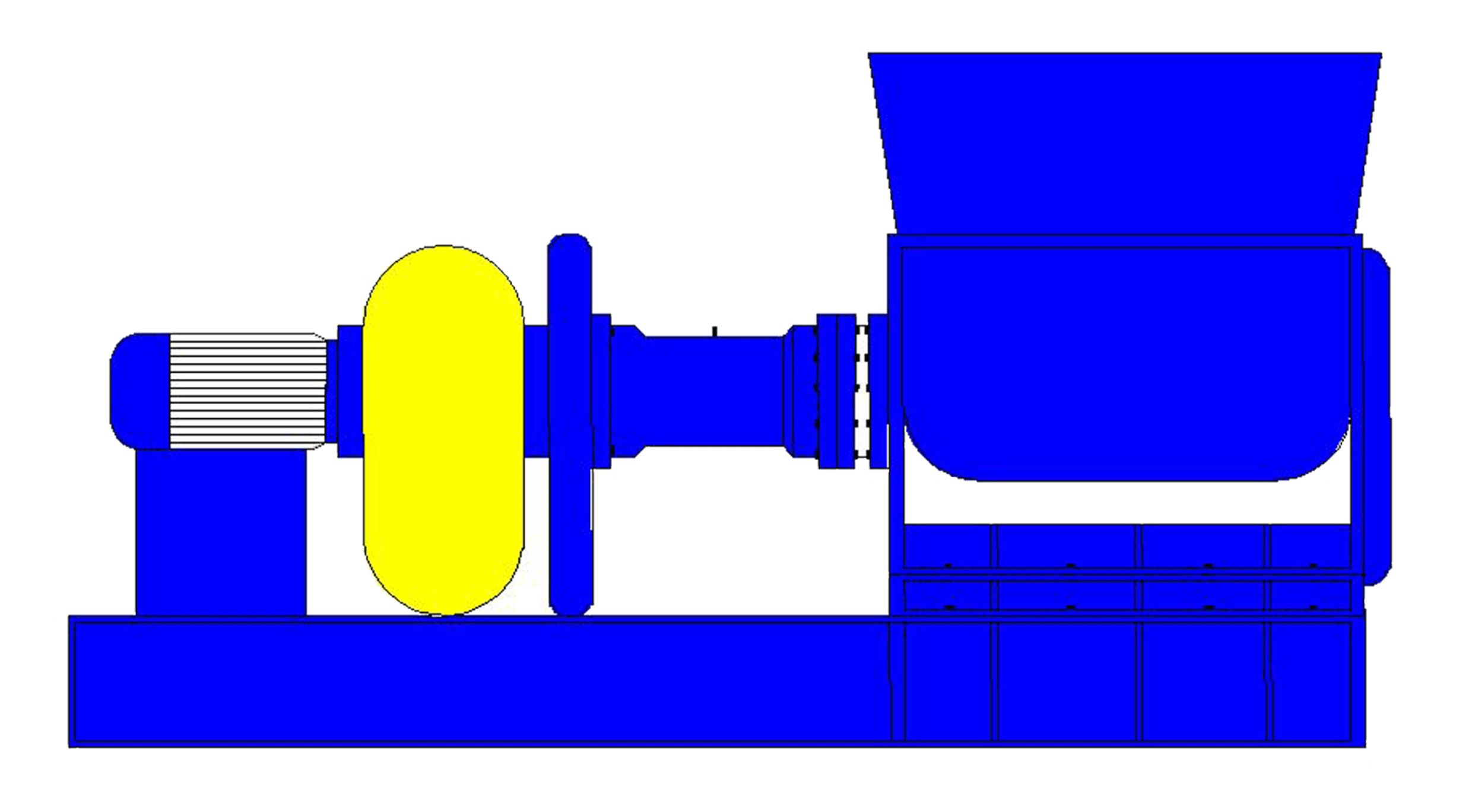

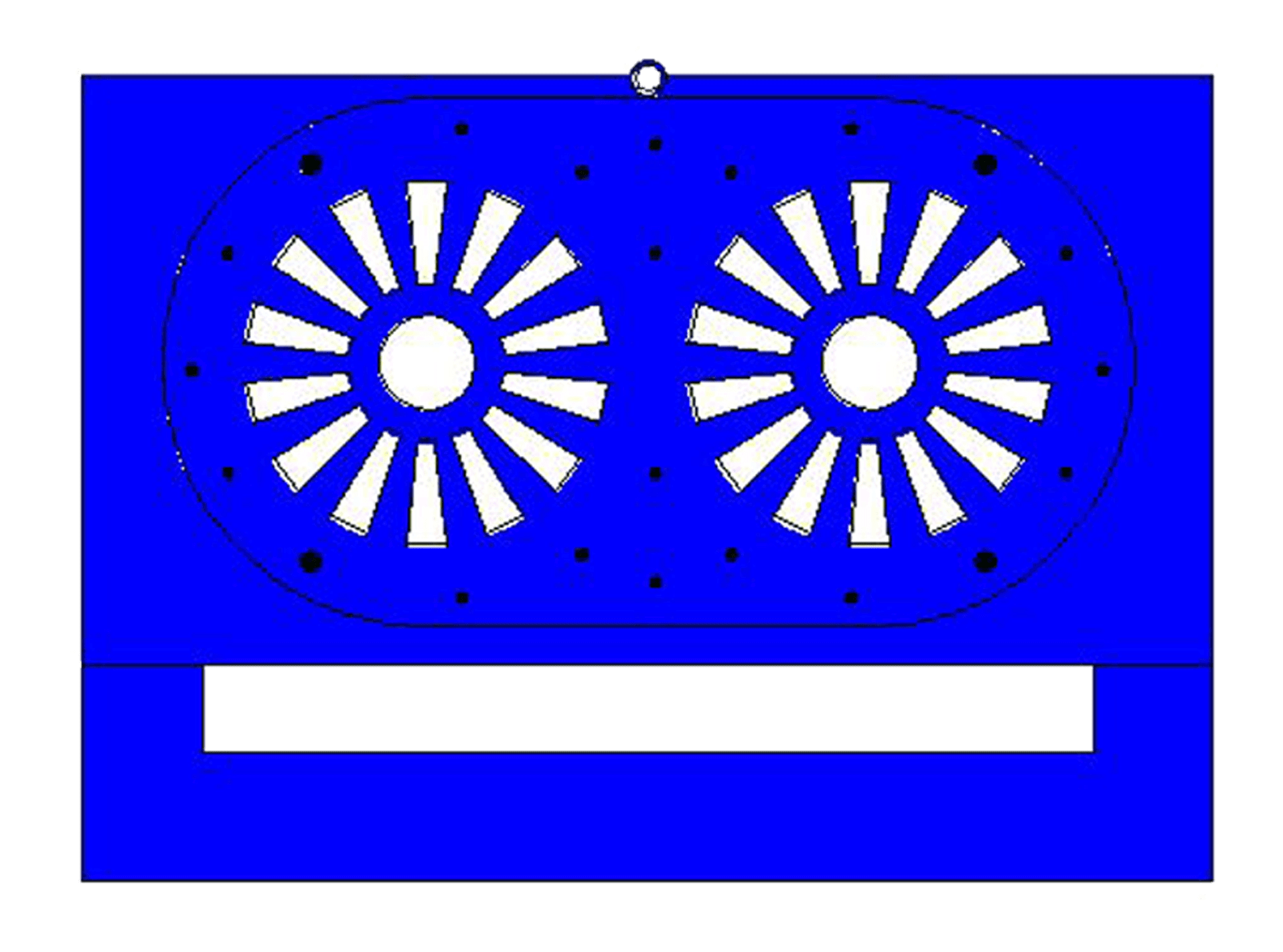

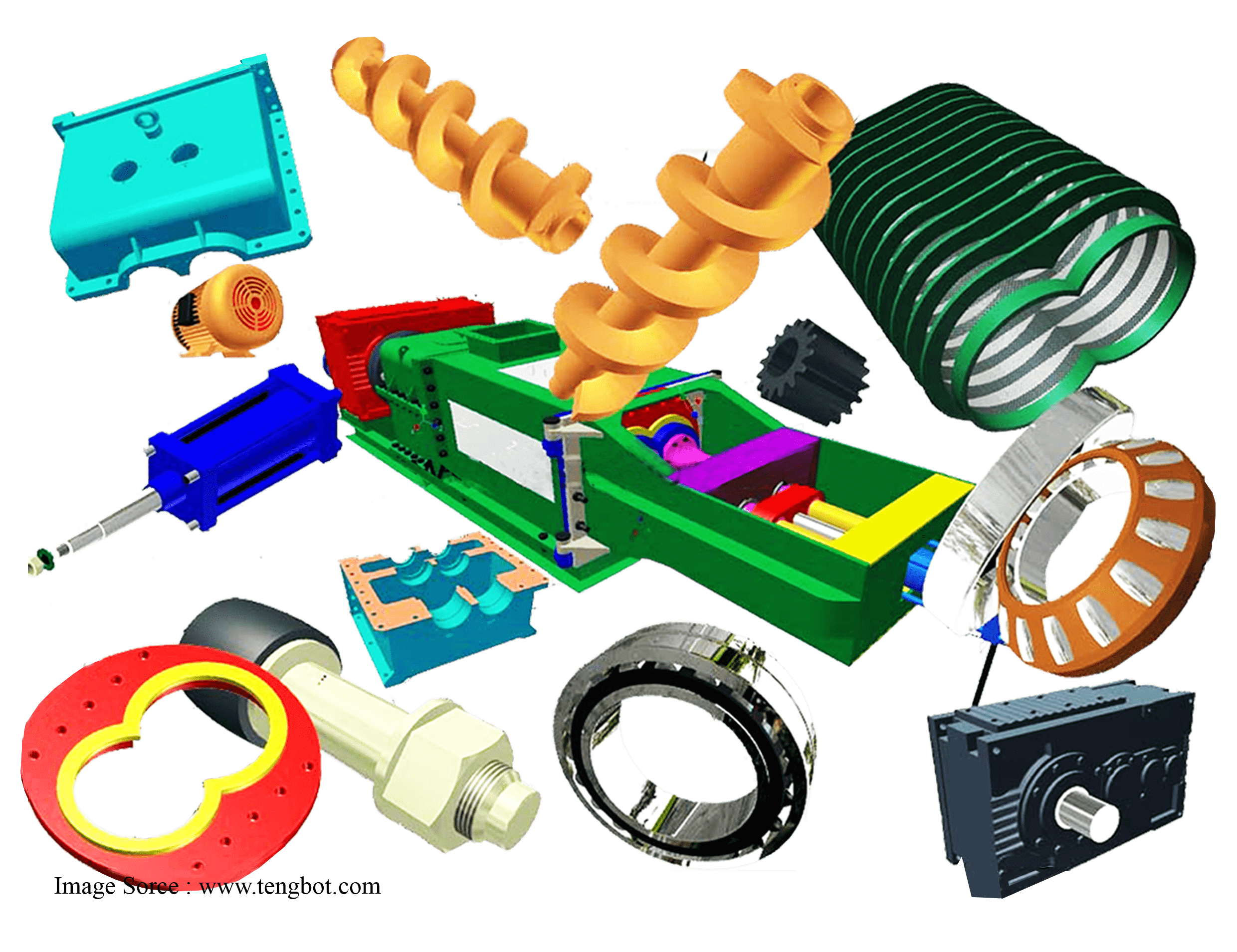

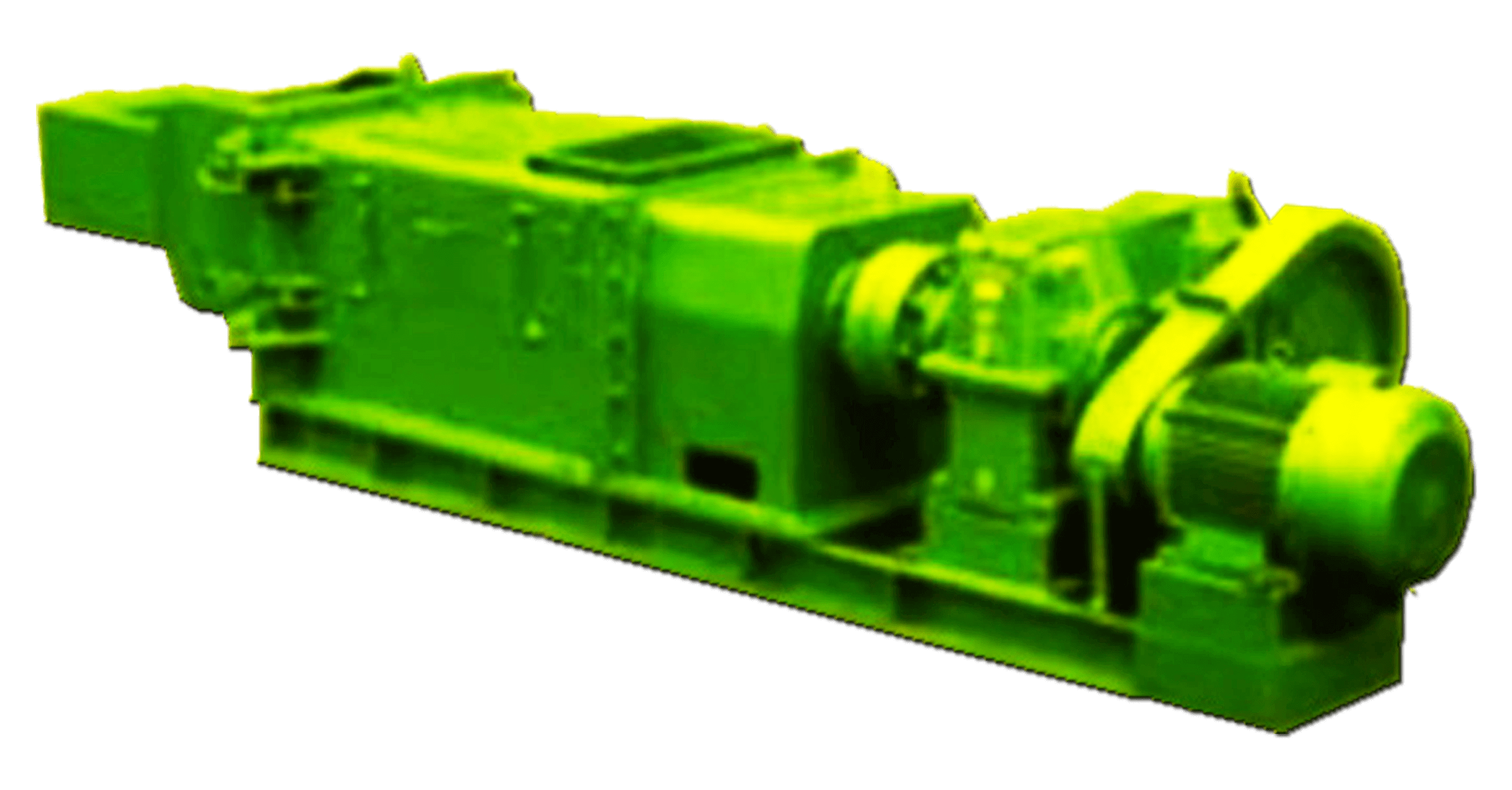

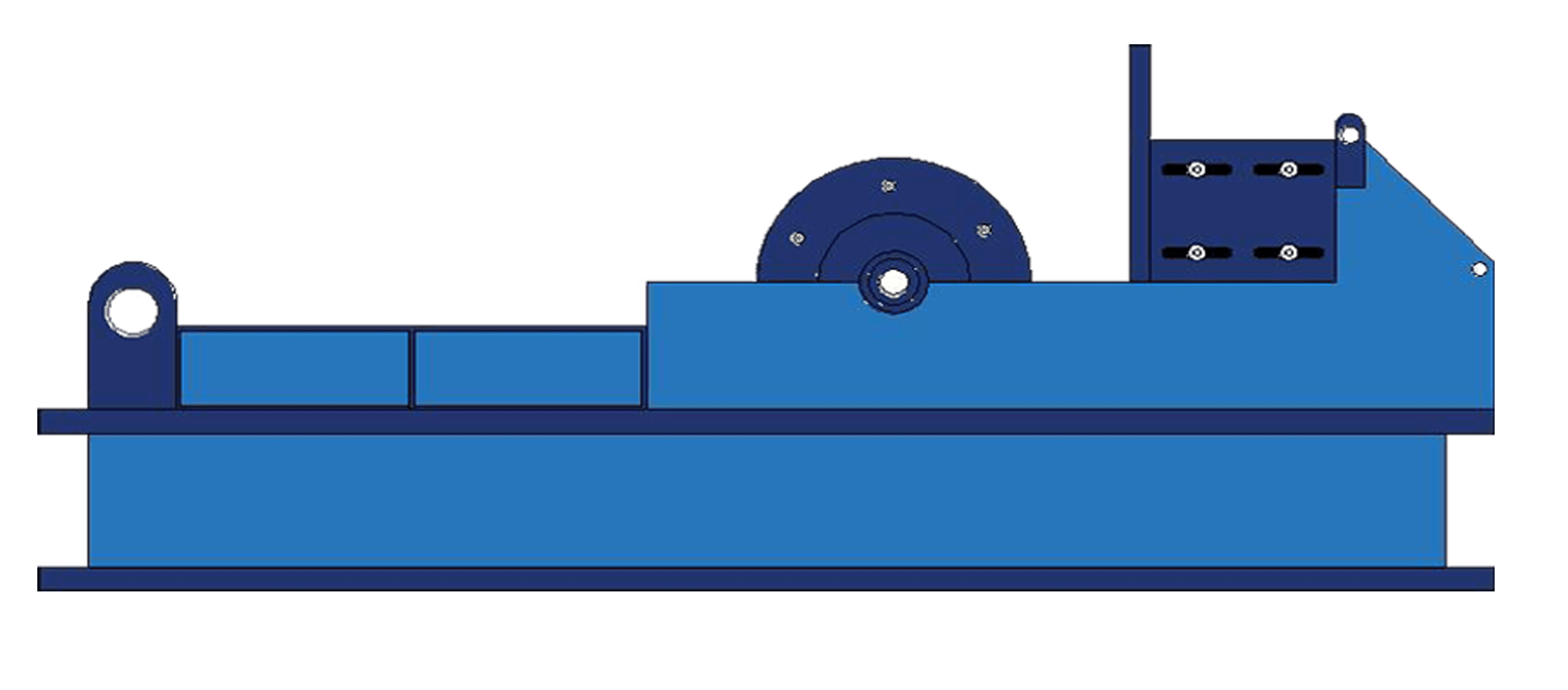

PRE BREAKER

- Twin screw prebreaker

- Easy to operate

- Easy to maintain

- Low power consumption

- Used very succesfully in reduction the lump size to smaller pieces

- Over intermediate and final stages

- Capacity 3 -5 t/h

- Motor 60 hp

Chamber : high gauge mild

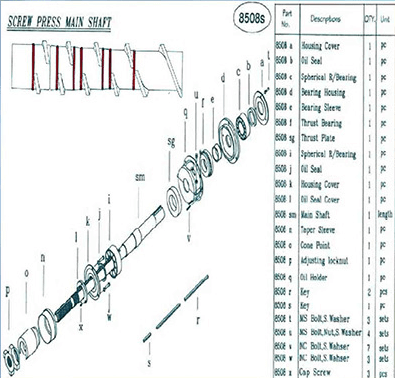

SCREW PRESS.

- Indoction motor 40 hp, 4p, 380 v, 50 hz, tclass f. Elektrim or equivalent

- Gear box

- Hydraulic power pack fully automatic control

- Switch board 40 hp, start delta and automatic amper control

- Slipping clutch for over load protection

- Hydraulic cylinder

- Flexible coupling

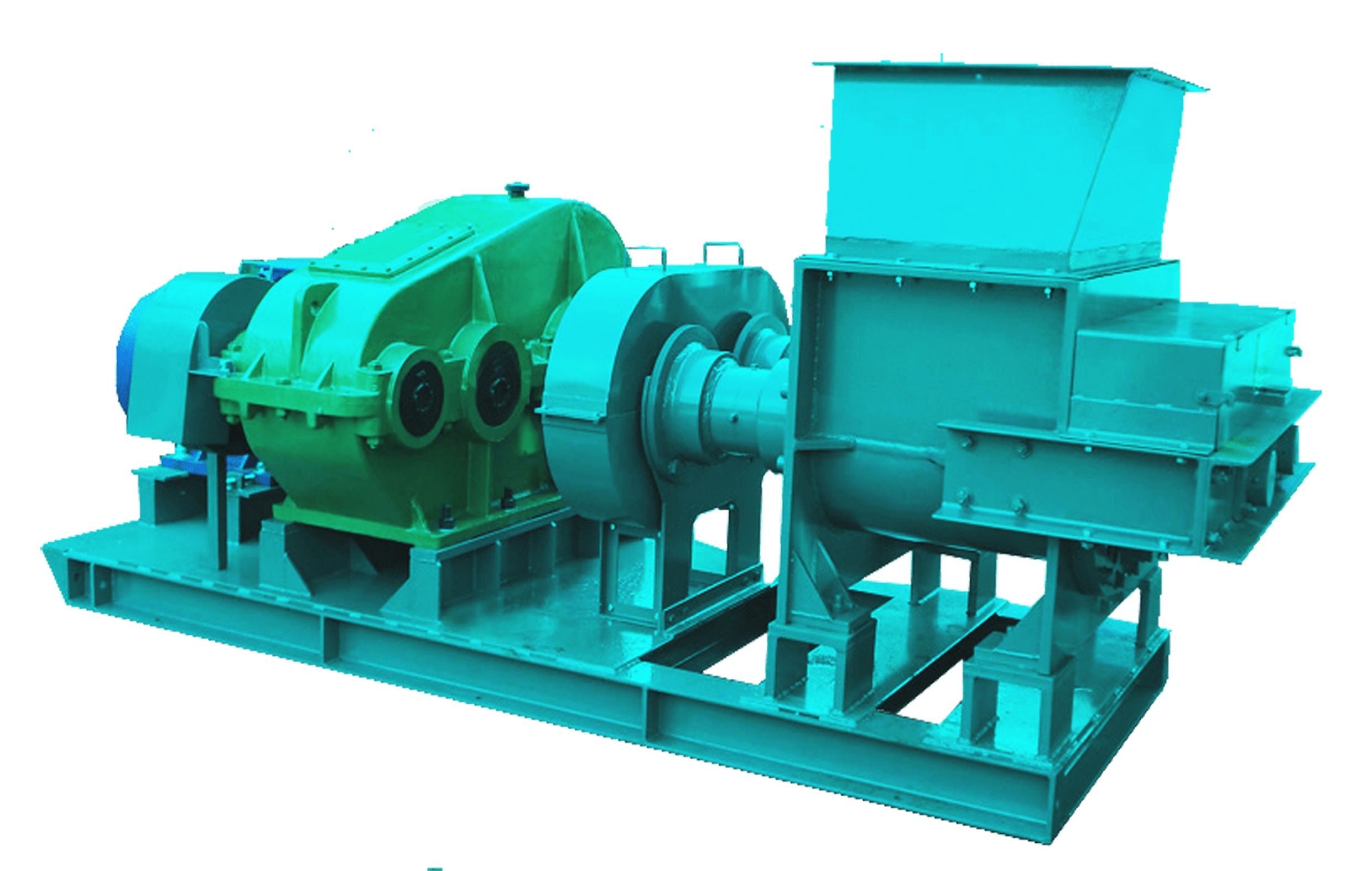

SHREDDER

The shredder is used very succesfully in the finak size reduction of crumb rubber, over intermediate and final stages.

The advantages of the shredder :

- Easy to operate, no special skill requirement

- Easy to maintain

- Low production cost

- Low investment

Using a diesel or electric motor source and adjusted to consumer demand.

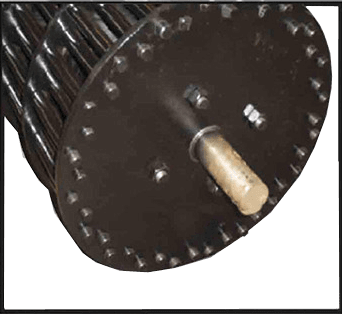

SUPER NUT CRACKER

Technical data

- Type : 16/18 hsnc

- System : integrated rotary system

- Rate capacity : 8-10 tonnes per hour

- Power : 11 kw ; 1498 rpm

- Enc : 97% – 99%

- Broken kernel rate : 15%

- Tolerance setting : 6-8 mm

Durability carbonizing rotor plates

Steel material

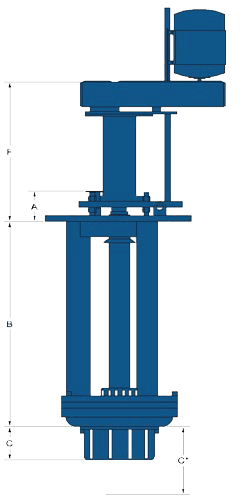

WATER PRESSURE TANK

- Indoction motor 40 hp, 4p, 380 v, 50 hz, tclass f. Elektrim or equivalent

- Gear box

- Hydraulic power pack fully automatic control

- Switch board 40 hp, start delta and automatic amper control

- Slipping clutch for over load protection

- Hydraulic cylinder

- Flexible coupling